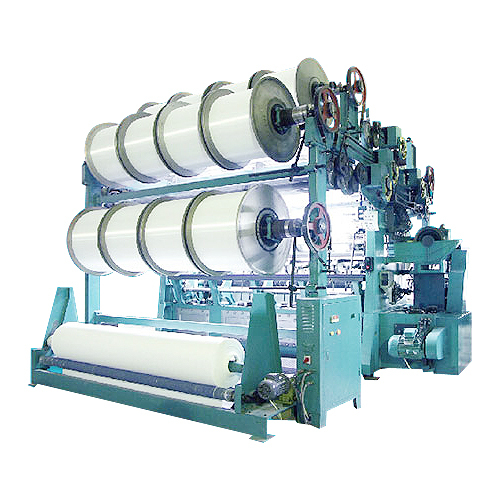

Plish Double Needle Bar Raschel Machine

Plish Double Needle Bar Raschel Machine Specification

- Knitted Type

- Pile (Plish) and base structure

- Lead Time

- 3060 days after order confirmation

- Application

- Curtain, upholstery, automotive fabrics, mesh, net, mattress

- System Support

- Touchscreen interface with multi-language support

- Control System

- Fully automated programmable logic controller (PLC)

- Condition

- New

- Needle

- Compound needle system for warp knitting

- Power

- 12 kW 20 kW (depending on model)

- Drive Type

- Servo motor drive

- Stitch Density

- Adjustable via control system

- Racking

- Available, precise lateral racking system

- Speed

- 400600 rpm (dependent on gauge and configuration)

- Color

- Blue & Silver (custom options available)

- Knitting Method

- Raschel double needle bar

- Dimension (L*W*H)

- 6000 x 3000 x 2500 mm (approx.)

- Weight

- Approx. 5,000 7,000 kg

- Gauge

- E18, E24, E28 (optional)

- Product Type

- Plish Warp Knitting Machine

- Function

- Producing plish/fancy industrial and home textile warp knits

- Fabric Take-Up

- Automatic Roll-Up Device

- Yarn Feeding System

- Electronic

- Maintenance Access

- Easy Front & Rear Access Panels

- Material Width

- up to 138 inches

- Safety Feature

- Emergency Stop & Interlock System

- Pattern Drive

- Electronic Jacquard Compatible

- Control Panel Interface

- Touchscreen HMI

- Fabric Output

- Plish, Velvet, Double-Pile Fabric

- Operating Voltage

- 380V/50Hz, 3 Phase

- Machine Frame

- Steel Welded Structure

- Lubrication

- Automatic Centralized System

- Noise Level

- 78 dB(A)

- Operational Temperature

- 5C to 40C

- Needle Bar Stroke

- Up to 50 mm

- Main Motor

- Frequency Converter Controlled

About Plish Double Needle Bar Raschel Machine

Plish Double Needle Bar Raschel Machine has been specifically designed to be used for knitting three-dimensional fabrics, high quality garments, and fine lingerie fabrics. It is most commonly employed for making superior grade sports fabrics and apparels. This machine has been equipped with a piezo jacquard system which provides ability to seamlessly & smoothly joining thick fabric sections. Plish Double Needle Bar Raschel Machine is also known for easily producing cylindrical shapes with minimal sewing and excellent appearance.

Features:

- Ideal for making ornamental cloth

- High-speed processing

- Homogenous thick & thin fabric surface texture

Cutting-Edge Warp Knitting Technology

The Plish Double Needle Bar Raschel Machine harnesses advanced raschel double needle bar knitting with an electronic yarn feeding system and a frequency converter-controlled main motor. Its servo motor drive and electronic jacquard compatibility enable complex patterns and high-speed operation, optimizing productivity for both intricate and standard designs.

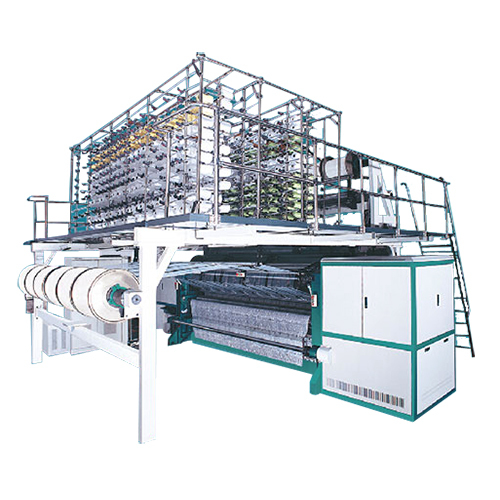

Versatile Applications Across Industries

Designed for flexibility, this machine produces plish, velvet, and double-pile fabrics with adjustable stitch density and gauge options (E18, E24, E28), making it ideal for curtains, upholstery, mesh, automotive, and mattress textiles. Custom color options and a wide material breadth expand its utility for diverse client needs.

User-Friendly Controls and Maintenance

Operators benefit from a responsive touchscreen HMI with multi-language support, ensuring easy programming and monitoring. Maintenance is streamlined by front and rear access panels, an automatic centralized lubrication system, and automatic roll-up fabric take-up, minimizing downtime and maximizing operational efficiency.

FAQs of Plish Double Needle Bar Raschel Machine:

Q: How does the Plish Double Needle Bar Raschel Machine ensure precise fabric production?

A: This machine uses an electronic yarn feeding system, fully automated PLC control, adjustable stitch density, and a servo-driven racking system to achieve uniform fabric structure and pattern accuracy, even at high speeds.Q: What types of fabrics can be produced with this machine, and what are its industry applications?

A: The machine is ideal for creating plish, velvet, and double-pile warp knit fabrics. Finished products serve a wide array of industries, including home textiles (curtains, upholstery), automotive, mattress, net, and mesh applications.Q: When can customers expect delivery after ordering this equipment?

A: Lead times for the Plish Double Needle Bar Raschel Machine range from 30 to 60 days post order confirmation, depending on the chosen configuration and model.Q: Where is the machine designed for use, and what are its operating conditions?

A: Engineered for industrial environments, it runs optimally at temperatures between 5C and 40C, with a recommended operating voltage of 380V/50Hz, 3 phase. Its robust frame ensures stability in diverse production settings within India or internationally.Q: What steps are involved in operating and maintaining this raschel machine?

A: Operation is streamlined through a touchscreen HMI. Maintenance tasks like lubrication and access for cleaning or repairs are simplified with automatic lubrication and easy-access front and rear panels, thus reducing manual intervention and downtime.Q: How does the machine enhance safety and operator comfort?

A: Safety features include an emergency stop button and an interlock system for immediate shutdown. The machine maintains a low noise level (78 dB(A)) to ensure a comfortable working environment and has user-friendly controls for safer handling.Q: What are the main benefits of using this machine for textile production?

A: Benefits include high-speed, consistent output of quality warp-knitted fabrics, versatility in fabric types, simple adjustment for different patterns or gauges, automated controls, and minimized maintenance requirementsall contributing to lower operating costs and greater productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Warp Knitting Machines Category

Automatic Plush Double Needle Bar Raschel Machine

Color : Standard Industrial Blue/Grey

Dimension (L*W*H) : 5800mm x 2600mm x 2400mm

Knitting Method : Double Needle Bar Raschel

Racking : Automatic

Stitch Density : Adjustable

Function : Knitting plush and similar pile fabrics

Automatic Multi Bar Raschel Machine

Color : Standard industrial grey with customizable options

Dimension (L*W*H) : Customized as per model; up to 6200 x 1900 x 2700 mm

Knitting Method : Warp knitting, Raschel type

Racking : Yes, multibar racking system enabled

Stitch Density : Adjustable via electronic control

Function : Versatile technical and meshfabric production

Double Needle Bar Raschel Machine

Color : Standard industrial grey

Dimension (L*W*H) : 8000mm x 2800mm x 2400mm

Knitting Method : Double Needle Bar Raschel

Racking : Fully automatic racking system

Stitch Density : Adjustable from 5 to 32 stitches/inch

Function : Manufacturing shade net, safety net, and sports net fabrics

Automatic Multi Bar Raschel Machine

Color : Industrial Grey/Blue

Dimension (L*W*H) : 7200 mm x 2500 mm x 2800 mm

Knitting Method : Warp Knitting, Raschel

Racking : Automatic Electronic Racking

Stitch Density : Easily Adjustable

Function : Automatic MultiBar Warp Knitting

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free