Woolen Cap Making Machines

Woolen Cap Making Machines Specification

- Knitting Method

- Flat Knitting

- Dimension (L*W*H)

- 2000 x 900 x 1500 mm

- Weight

- 700 Kg

- Gauge

- 3G, 5G, 7G, 12G, 14G

- System Support

- Single/Double System

- Needle

- High-speed Stainless Steel

- Power

- 1.5 kW

- Lead Time

- 15-20 Days

- Drive Type

- Servo Motor Drive

- Product Type

- Woolen Cap Making Machine

- Application

- Woolen Cap Production

- Function

- Automatic Cap Knitting

- Stitch Density

- Adjustable, 1-50 Grade

- Racking

- Double Racking

- Control System

- Intelligent Touch Screen Programmable

- Color

- Industrial Grey/Blue

- Speed

- 1.2 m/s Max Knitting Speed

- Condition

- New

- Knitted Type

- Circular/Flat

- Pattern Transfer

- USB/Network Compatible

- Memory Capacity

- 1000 Pattern Storage

- Voltage

- 220V / 380V (Customizable)

- Material Compatibility

- Wool, Acrylic, Blended Yarns

- Noise Level

- <70 dB

- Lubrication System

- Automatic Centralized

- Yarn Feeder

- 4-6 Sets

- Display Panel

- 7-Inch LCD Touch Panel

- Production Capacity

- 200-250 caps/day (depends on design complexity)

- Safety Features

- Emergency Stop, Overload Protection

About Woolen Cap Making Machines

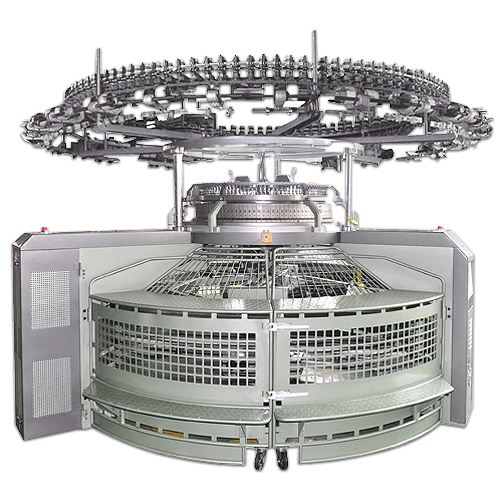

Our domain expertise has enabled us to come up with a quality assured Circular Grain Knitting Machine. This is hugely known for it's low energy consumption, widely acknowledged high speed product, ergonomic designs, seamless quality, dependability and durability. It is used for making variegated colorful monkey caps, woolen caps, etc,. Thus, our Circular Grain Knitting Machine is massively in demand among the users. Spaced out from this, in order to match the preferences of the clients, we manufacture this machine in submitted specifications and sizes.

Efficient Production with Intelligent Controls

The flat knitting machine offers a streamlined workflow, thanks to a 7-inch LCD touch panel and an intelligent programmable system. Operators can store up to 1000 cap patterns and easily transfer new designs via USB or network. Adjustable stitch density and multiple yarn feeding sets allow for quick adaptation to diverse production requirements and complex cap styles.

Unmatched Versatility and Compatibility

Compatible with wool, acrylic, and blended yarns, this cap knitting machine supports various gauges (3G to 14G) and both circular and flat knitting methods. Its adjustable stitch density and double racking expand creative possibilities, while the high-speed stainless steel needles and 1.2 m/s max speed deliver consistent, professional results.

Robust Build and Safety Assured

Built to industrial standards, the machine maintains a quiet operation below 70 dB and includes an emergency stop and overload protection for operator safety. The automatic centralized lubrication prolongs machine life, while heavy-duty components ensure stable performance throughout daily production. Standard lead time for delivery is 1520 days.

FAQs of Woolen Cap Making Machines:

Q: How does the automatic woolen cap making machine operate?

A: The machine utilizes an intelligent touch screen interface for programming patterns and controlling production. You can insert your design via USB or network transfer, select yarns, and begin automatic knitting. Its servo motor drive and centralized lubrication enable smooth, efficient, and low-maintenance operation throughout each cycle.Q: What types of yarn and materials are compatible with this machine?

A: This model supports a wide range of yarns, including wool, acrylic, and blended fibers. The adjustable system accommodates different gauges (3G, 5G, 7G, 12G, and 14G), making it versatile for various cap textures and thicknesses.Q: Where can this machine be installed and used effectively?

A: Ideal for textile factories, distribution centers, and suppliers across India, the machines compact industrial design (2000 x 900 x 1500 mm) suits both large-scale manufacturing floors and mid-sized production units requiring high output and operational efficiency.Q: What is the process for uploading and managing cap patterns?

A: Cap designs can be conveniently uploaded via USB or through network connectivity directly to the 7-inch LCD touch panel. The system has a storage capacity for up to 1000 patterns, allowing efficient switching and management of designs based on market trends.Q: When can I expect delivery and set-up for the machine?

A: Standard lead time for delivery is approximately 1520 days from order confirmation. On-site installation and set-up can be coordinated with the distributor or supplier to ensure smooth commissioning and operational training.Q: What safety and maintenance features does this machine offer?

A: Safety is ensured through emergency stop controls and overload protection systems. Maintenance is simplified by the automatic centralized lubrication system, which keeps all critical components well-oiled, reducing wear and ensuring dependable, long-term operation.Q: What benefits does this machine provide for woolen cap production?

A: The automatic cap knitting machine boosts productivity (up to 250 caps per day), reduces manual labor, and increases design flexibility due to its versatile pattern management and yarn compatibility. Its robust build, quiet operation, and safety features enhance overall production value and workforce safety.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Circular Knitting Machines Category

Double Side Computerized Jacquard Machine

Application : Sweater, Sportswear, Fashion Garments Manufacturing

Condition : New

Product Type : Jacquard Knitting Machine

Drive Type : Servo Motor

Function : Doubleside knitting, Jacquard Pattern production

Color : Grey/Blue

Single Jersey Open-End Knitting Machines

Application : Textile & Garments Industry

Condition : New

Product Type : Knitting Machine

Drive Type : Servo Motor

Function : Circular KnittingProduce Single Jersey Fabrics

Color : BlueGrey

Cam System

Application : Knitting Machine Component

Condition : New

Product Type : Cam System

Drive Type : Servo Motor

Function : High Precision Transfer, Increased Knitting Efficiency

Color : Grey

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free