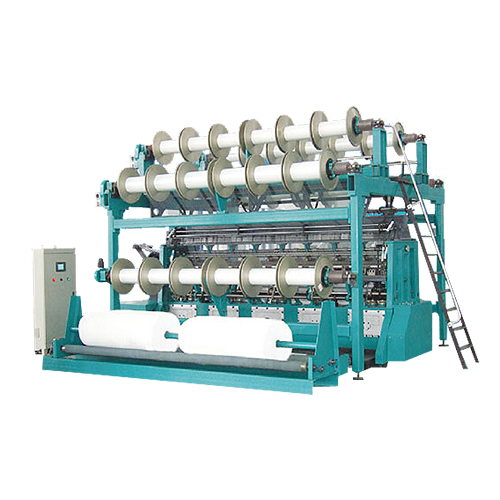

Double Jersey Knitting Machine

Double Jersey Knitting Machine Specification

- Product Type

- Double Jersey Knitting Machine

- System Support

- Single/Double System

- Needle

- High Carbon Steel Needles

- Function

- Fabric Production / Knitting

- Power

- 5.5 kW

- Dimension (L*W*H)

- 2300 mm x 2300 mm x 2100 mm

- Knitted Type

- Double Jersey

- Speed

- Up to 25 RPM

- Application

- Textile Industry, Knitting Mills

- Knitting Method

- Circular Double Jersey

- Condition

- New

- Racking

- Available

- Drive Type

- Servo Motor Drive

- Control System

- Computerized Panel

- Stitch Density

- Adjustable

- Weight

- Approximately 2,200 kg

- Color

- Grey/Blue

About Double Jersey Knitting Machine

- We are a reckoned manufacturer, exporter, distributor, importer and supplier of Double Jersey Knitting Machine

- It is widely used for producing varied kinds of fabric in high quality.

- This is manufactured using sophisticated techniques and quality assured raw materials.

- Thus, it is known for its high speed, seamless performance, high efficiency effect and longer service life.

Efficient Circular Double Jersey Knitting

Our machine is built for optimized fabric production using the circular double jersey method. It accommodates various fabric requirements for the textile industry, providing versatility and reliability. Designed to streamline operations, it supports single and double systems, ensuring flexibility across manufacturing needs.

State-of-the-Art Computerized Controls

Equipped with an advanced computerized panel, the machine facilitates precise adjustments, easy operation, and real-time monitoring. The user-friendly interface allows operators to seamlessly control speed, stitch density, and pattern, optimizing workflow and minimizing downtime.

Durable Construction and Reliable Performance

Engineered with robust materials, including high carbon steel needles and a strong frame, this machine ensures sustained performance under intensive usage. The servo motor drive not only offers efficiency but also consistent motion, helping maintain the quality of produced fabrics.

FAQs of Double Jersey Knitting Machine:

Q: How does the Double Jersey Knitting Machine with Racking enhance fabric production efficiency?

A: This machine leverages a circular double jersey knitting method and computerized controls to provide rapid, high-quality fabric output. Its servo motor drive and adjustable stitch density mean minimal manual intervention and greater precision, thus maximizing production efficiency.Q: What applications are best suited for this knitting machine?

A: The machine is ideal for textile manufacturing facilities and knitting mills. Its particularly effective for producing double jersey fabrics that require consistency and speed, meeting the demands of the commercial textile industry in India.Q: When should I adjust the stitch density, and how is it accomplished?

A: Stitch density should be modified when you need to change fabric thickness or texture. The computerized panel allows users to easily adjust this setting, ensuring each batch meets specific requirements.Q: Where can this machine be installed, considering its dimensions and weight?

A: With dimensions of 2300 mm x 2300 mm x 2100 mm and a weight of approximately 2,200 kg, the machine is suitable for large factory spaces or knitting mills equipped with sturdy flooring and adequate clearance.Q: What is the operational process for the Double Jersey Knitting Machine?

A: The process involves loading yarns, setting the required pattern and stitch density using the computerized panel, and starting the machine. The servo motor drive ensures smooth operation while the high carbon steel needles knit fabric efficiently.Q: How does the machine benefit fabric manufacturers?

A: Manufacturers benefit from high-speed production (up to 25 RPM), consistent quality via adjustable parameters, reduced manual errors, and the durability of components, resulting in increased output with lower long-term operational costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Warp Knitting Machines Category

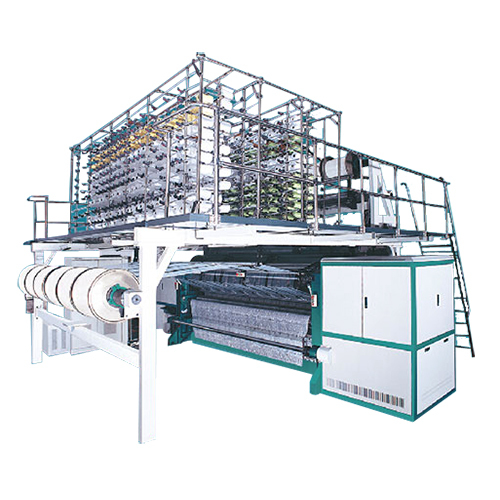

Double Needle Bar Raschel Machine

Knitting Method : Double Needle Bar Raschel

Condition : New

Product Type : Warp Knitting Machine

System Support : Electronic Pattern Drive, Jacquard Device

Function : Manufacturing shade net, safety net, and sports net fabrics

Power : 15 kW

Automatic Double Needle Bar Raschel Machine

Knitting Method : Double needle bar Raschel

Condition : New

Product Type : Industrial Knitting Machine

System Support : Electronic yarn feeding, pattern drive system

Function : For producing net, lace, spacer fabrics, mattress mesh, technical textiles

Power : 15 kW

Plish Double Needle Bar Raschel Machine

Knitting Method : Raschel double needle bar

Condition : New

Product Type : Plish Warp Knitting Machine

System Support : Touchscreen interface with multilanguage support

Function : Producing plish/fancy industrial and home textile warp knits

Power : 12 kW 20 kW (depending on model)

Automatic Multi Bar Raschel Machine

Knitting Method : Warp Knitting, Raschel

Condition : New

Product Type : MultiBar Raschel Machine

System Support : 612 Bar

Function : Automatic MultiBar Warp Knitting

Power : 7.5 kW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS