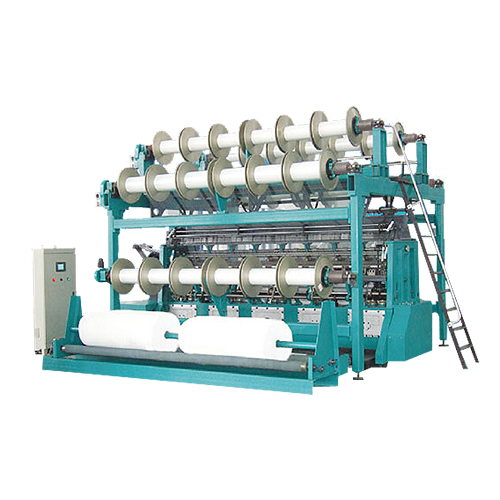

Plush Double Needle Bar Raschel Machine

Plush Double Needle Bar Raschel Machine Specification

- System Support

- 6-needle/7-needle/8-needle Systems

- Stitch Density

- Adjustable

- Condition

- New

- Function

- Plush Fabric Knitting

- Weight

- Approx. 9000 kg

- Needle

- Compound Needle

- Drive Type

- Servo Motor

- Control System

- PLC Touch Screen

- Color

- Sky Blue / Customized

- Speed

- Up to 600 rpm

- Racking

- Available

- Product Type

- Plush Fabric Knitting Machine

- Dimension (L*W*H)

- 5800 x 2200 x 2400 mm

- Power

- 15 kW

- Lead Time

- 30-60 days

- Knitting Method

- Double Needle Bar Raschel

- Gauge

- E18/E22/E24

- Application

- Home Textile, Garment, Blanket, Carpet

- Knitted Type

- Plush / Terry / High-pile

- Humidity Tolerance

- 85% RH

- Material Compatibility

- Polyester, Cotton, Acrylic, Blended Yarns

- Main Shaft Drive

- Direct Drive

- Spare Parts Kit

- Included

- Noise Level

- <85 dB(A)

- Output Fabric Width

- Up to 220 inches

- Number of Bars

- Up to 12 Bars

- Operator Panel

- Large Multi-language Touchscreen

- Operating Temperature

- 040C

- Safety Feature

- Emergency Stop & Safety Guards

- Fabric Take-up Device

- Auto Roll-up

- Pattern Drive

- Electronic Jacquard or Chain Link

- Voltage

- 380V / 50Hz (Customizable)

- CE Certification

- Available

- Lubrication

- Centralized Automatic Lubrication

- Yarn Feeding System

- Automatic

About Plush Double Needle Bar Raschel Machine

- Our company is a prominent supplier, manufacturer, exporter, distributor and importer of Plush Double Needle Bar Raschel Machine.

- This is made keeping in mind the set parameters of the arena using modern technology and latest machines.

- Therefore, our offered machine is hugely acclaimed among the masses for its dependability, remarkable performance, noted operation and many more.

Advanced Automation and User-Friendly Operation

Equipped with a fully automatic yarn feeding system and a large multilingual touchscreen, the Raschel machine streamlines the knitting process. The PLC control and servo motor drive system boost production efficiency while minimizing manual intervention. Operators benefit from an intuitive interface and comprehensive safety features, such as emergency stop and guarding, ensuring both productivity and safety.

Versatility and Superior Fabric Quality

Tailored for plush, terry, and high-pile fabrics, this machine accommodates up to 12 bars and multiple needle systems (6, 7, 8-needle support). It is compatible with a range of yarn materials such as polyester, cotton, acrylic, and blends, producing fabrics up to 220 inches wide. Adjustable stitch density allows for customized fabric textures, meeting the demands of varied applications in textiles.

Durability and Compliance

Built to operate in environments with temperatures from 040C and up to 85% humidity, this machine comes CE certified and is crafted with robust components. It features centralized automatic lubrication and comes with a spare parts kit, ensuring reliable, long-term performance with reduced maintenance needs. Customizable voltage and color options allow seamless integration into existing production lines.

FAQs of Plush Double Needle Bar Raschel Machine:

Q: How does the automatic yarn feeding system improve efficiency on this Plush Raschel Machine?

A: The automatic yarn feeding system delivers consistent yarn supply to the needles, minimizing manual intervention and reducing the risk of thread breakages or inconsistencies. This leads to higher production speed, improved fabric quality, and less downtime for operators.Q: What types of fabrics and yarns can be processed with this machine?

A: This Raschel machine is capable of knitting plush, terry, and high-pile fabrics using polyester, cotton, acrylic, and blended yarns. Its compatibility with multiple gauges and needle systems allows manufacturers to produce a wide range of textures and thicknesses for different textile applications.Q: When is CE certification important for textile machinery?

A: CE certification demonstrates the machines compliance with European safety, health, and environmental standards. This ensures operators safety, eases importation into international markets, and provides assurance of quality and reliability, making it crucial for manufacturers aiming for global reach.Q: Where can this machine be effectively utilized within the textile industry?

A: The Plush Double Needle Bar Raschel Machine is ideal for use in home textile manufacturing, garment factories, blanket and carpet production facilities, especially where high-quality plush or high-pile fabrics are required. Its adaptability suits both large-scale and specialty textile operations.Q: What is the benefit of centralized automatic lubrication in this machine?

A: Centralized automatic lubrication consistently delivers the right amount of oil to all critical moving parts, reducing wear and tear, enhancing longevity, and decreasing routine maintenance downtime, thereby optimizing overall machine performance.Q: How does the electronic Jacquard/chain link pattern drive system function?

A: This advanced pattern drive system allows for intricate and variable patterns to be programmed directly into the machine. Whether using electronic Jacquard for complex designs or a robust chain link for repetitive patterns, operators gain flexibility and precision in fabric design and production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Warp Knitting Machines Category

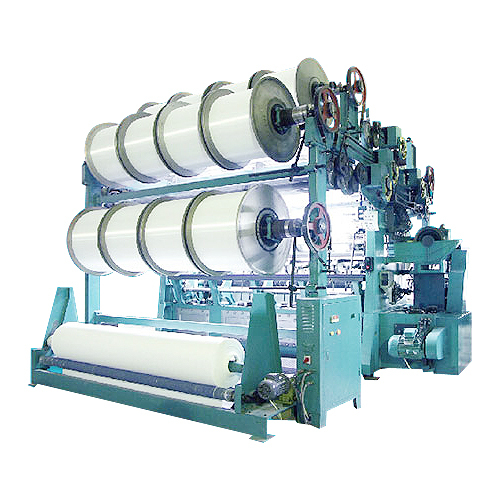

Automatic Double Needle Bar Raschel Machine

Product Type : Industrial Knitting Machine

Color : Standard industrial gray / blue

Control System : Programmable PLC with touch screen

Drive Type : Servo motor driven

Dimension (L*W*H) : 6400 x 2000 x 2600 mm

Power : 15 kW

Automatic Plush Double Needle Bar Raschel Machine

Product Type : Plush Fabric Making Machine

Color : Standard Industrial Blue/Grey

Control System : Digital Touch Panel

Drive Type : Servo Motor Drive

Dimension (L*W*H) : 5800mm x 2600mm x 2400mm

Power : 18.5 kW

Plish Double Needle Bar Raschel Machine

Product Type : Plish Warp Knitting Machine

Color : Blue & Silver (custom options available)

Control System : Fully automated programmable logic controller (PLC)

Drive Type : Servo motor drive

Dimension (L*W*H) : 6000 x 3000 x 2500 mm (approx.)

Power : 12 kW 20 kW (depending on model)

Double Needle Bar Raschel Machine

Product Type : Warp Knitting Machine

Color : Standard industrial grey

Control System : Intelligent touch panel operation

Drive Type : Servo motor drive

Dimension (L*W*H) : 8000mm x 2800mm x 2400mm

Power : 15 kW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free